How Spray Trucks Work Today

The District maintains a fleet of nine spray trucks which dispense a very fine mist of insecticide. This is known as an ultra-low-volume (ULV) technique. The trucks are equipped with a chemical tank and pump combined with a computer flow-control and driver guidance device. The photos on the right depict the basic spray machine and nozzle. There is a small engine which drives an air compressor. The spray nozzle is chosen to create droplets of the correct size range at the pressure the air compressor delivers. The valve on the nozzle cuts off the spray instantly if the need arises. Otherwise, the flow is completely controlled by the computer guidance unit which can switch it on or off as appropriate during the spray route.

A computer-regulated pump controls the amount of insecticide delivered per mile traveled. If the truck goes faster, the pump increases the output of the product; if the truck slows down, the volume is decreased. By utilizing the variable flow pump, the same amount of insecticide is applied to the treated area regardless of how fast the truck is traveling.

The drivers are directed by a sophisticated GPS guidance system. It’s almost like a video game; follow the directions and make the blue roads turn red on the screen. This greatly reduces the time it takes to train new drivers and minimizes the number of mistakes and missed streets. Once a new driver has experience with several zones, they are prepared to spray any zone.

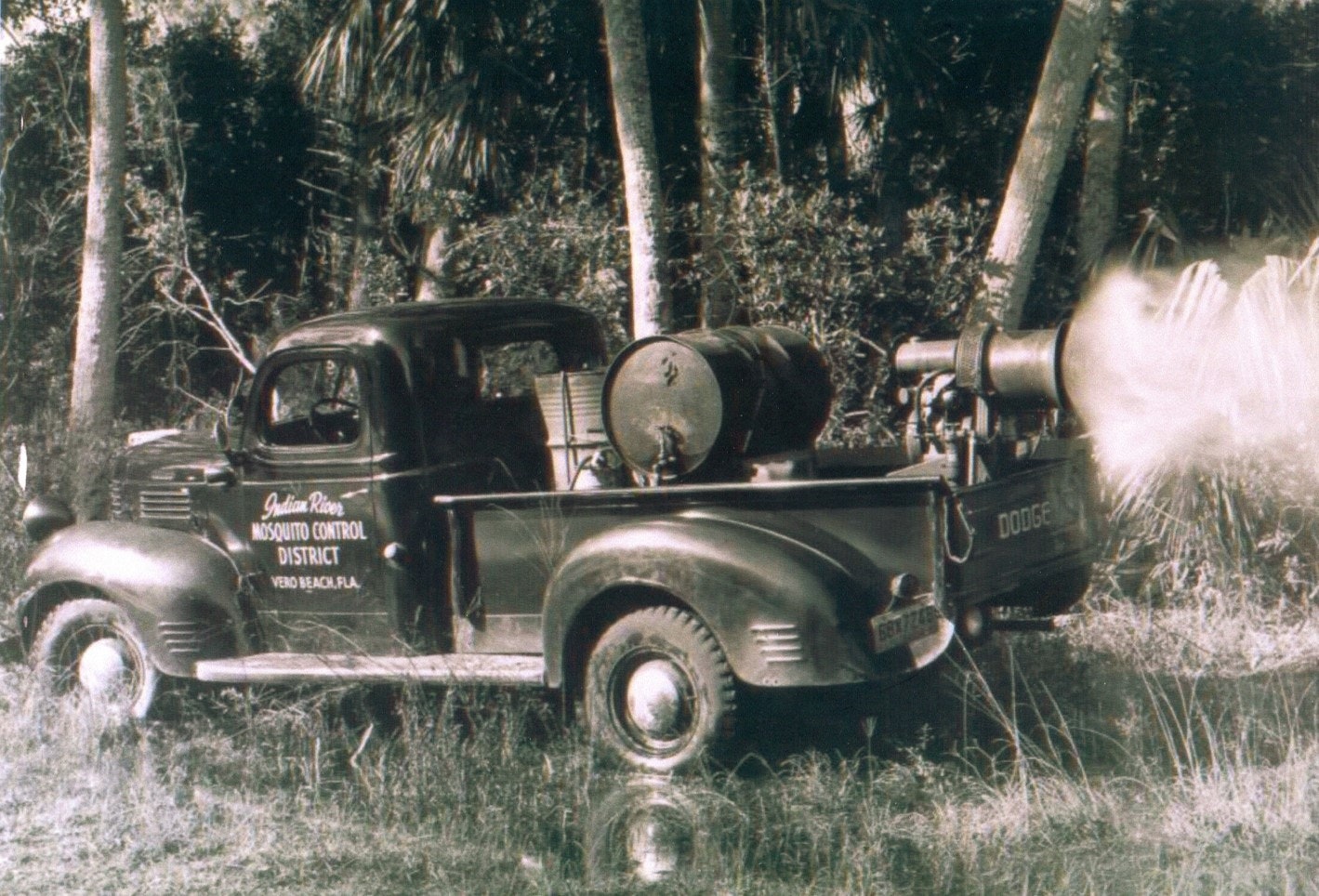

How Spray Trucks Worked in Years Past

From the 1940s through the late 1960s, IRMCD applied adulticides (chemicals applied to kill adult flying mosquitoes) which were commonly diesel fuel mixed with an insecticide. The formulation was heated until a thick white oily fog was generated which was applied from a truck. Back then, none of this was a concern in an underpopulated county. Today, not only would this fog be a traffic hazard but also has an unpleasant lingering odor and environmental concerns. The old fogging trucks were meant to work at one speed - 5 miles per hour. These were later "improved" to spray at about 10 miles per hour. It took days to spray just a portion of the county. Sometimes the diesel fog would ignite, causing a large fireball behind the truck.

Somewhat greater flexibility was achieved when we started using ULV methods. A speedometer cable ran from the truck transmission directly to a small chemical pump. This kept the amount of spray proportional to the vehicle speed up to about 30 miles per hour. By the late 70s, a home-built electronic flow monitor was added so the driver could monitor the output.

In the mid-80s our preference was to use a fully-electronic flow control but affordable commercial units were agricultural, built for much higher volumes of chemicals than we use for mosquito control. So, we designed and built suitable units ourselves in-house.

These took an electronic speed code from the vehicle and a small motor replaced the cable drive on the pumps. This allowed the trucks to be calibrated precisely and to go a little faster - thereby allowing more to be completed in a nighttime spraying. These units also provided basic performance reports including miles-sprayed and top-speed. An updated model added GPS tracking so maps indicating vehicle location, direction, speed, and spraying status could be created.

Today we use a fully GPS-controlled system with driver-guidance features and the ability to automatically cut off spray when passing by sensitive areas (near bee hives for example).